Lost and Sound by Paul Fischer

Printed by kind permission from the “Woodworker” January 1985

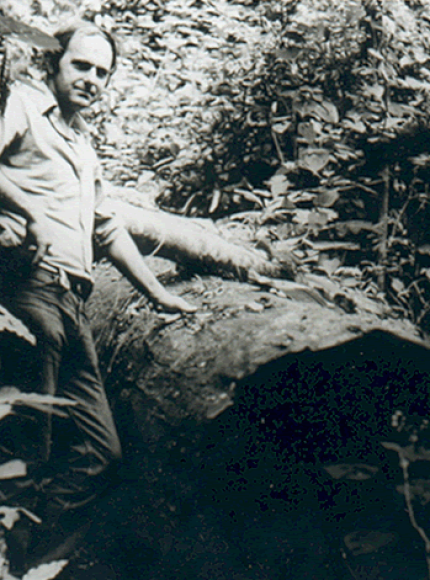

Two craftsmen in music explore the fascinations and frustrations of timbers and timbres. Paul Fischer describes his journey through the devastated forests of Brazil in search of a rosewood alternative.

The classical guitar is the most important instrument using rose- wood, as it is directly related to the instrument’s tone. For the past ten years this wood has been extremely difficult to obtain, and so the small quantity reaching Europe has been ridiculously expensive and not very high quality. The problem has been exacerbated by the Brazilians’ insistence on payment in US dollars and their own inflation of 140%.

Before the supplies of rosewood became totally exhausted it seemed an appropriate time to undertake a serious study in Brazil and establish once and for all the true situation, and while I was there seek suitable alternative woods for further study. Bearing in mind the vast range of similar species available from that region and the success of work already done with a few of the woods from Brazil, I decided to concentrate on other woods from South America.

Many guitar makers have changed to the well established alternative East Indian rosewood (Dalbergia latifolia), which has proved most satisfactory, but I felt it should not be considered the only alternative.

I travelled throughout Brazil, starting first in São Paulo, then on to Belem on the Equator and the Amazon region. Belem is the most important port for the export of timber from the state of Para and the Amazonas.

Visiting the main docks in Belem, I spent some time with two important timber merchants both supplying mahogany (Swietenia macrophylla) and cedar (Cedrela odorata) to the U .S.A. and Europe. Directors of both companies informed me that mahogany from the Para region would be finished within three years and they were preparing to go over to plywood production. Both mahogany and cedar are woods commonly used in the manufacture of guitars.

After four days in Belem I flew to the State of Bahia. This whole region is engaged in the timber trade, felling, converting and transporting timber to the ports and cities of the south. There being no railway, all timber is transported by road and very bad roads at that. It is not uncommon for sections of the road to disappear; with very little forest remaining, the light soil is easily washed away taking the road with it. I travelled the whole length of Bahia State and the picture was the same everywhere — vast areas of barren hillside with nothing but solitary dead burnt tree trunks, a testimony to the once flourishing forest and its fiery destruction. There were only a few small pockets of trees left, quite often on difficult ridges or terrain.

I gathered the System is to cut only the mature trees, perhaps 30% of the forest, and the remainder is burned to clear the land quickly for cattle or sugar cane. Much of the forest is owned by peasant farmers and they have a duty to re-plant three trees for each one cut down, but because of the remoteness of many of the farms and poor communications, they rarely do it; their wish is for a regular income. In all my travels I saw no indications of replanting, a failure made more urgent because of the destruction of future supplies by fire, not to mention the eco-system destroyed likewise. Burning is not confined just to Bahia; it is common practice throughout Brazil.

My study was centred in Bahia becausethe best rosewood only grows in that state, and a number of other interesting species are found there. I visited many mills and timber merchants, and it was clear rosewood had not passed their saws for a very long time. The sawyers and merchants just shook their heads at my enquiries about rosewood, and came eventually to the conclusion that commercially at least, it is extinct.

I saw a number of very large sawmills in the throes of closing and even some of the smaller ones were short of work, a clear indication of the depletion of the forest. They are now mostly converting timber for domestic use, using any tree at all. There appears to be no selection of the most suitable tree for a specific purpose — even ebony was used for railway sleepers!

The mills are particularly primitive; there is very little lifting gear and the logs are manhandled, even the largest of 4-5ft diameter. They move logs from truck to saw carriage with crowbars and winches, a very dangerous operation. The saws themselves are equally primitive, large belts and blades exposed and unguarded. Most common was the frame saw. Although of vintage manufacture and design, it seems particularly suitable for cutting some of the extremely hard woods, such as ironwood and pernambuco.

After nine days in the region of Itamaraju I left for Vitoria, in the state of Espirito Santo, to visit Atlantic Veneers, a veneer and plywood factory which also holds a good stock of domestic timber in log and plank form for general sale. We were shown six small logs of rosewood, each about l5 cu ft, for which the price quoted was $8,000!

I found three other interesting woods in their yard, all of promising colour, weight and tonal quality. Unfortunately the company refused to sell me some for my work, only dealing, like any big merchant, in large quantities. The three woods of interest were macacouba (Platymiscium), cardinal wood (Bsimum paraenses), and sabourana (Swartzia laevicarpae).

On my return to São Paulo, I spent a full day studying the 2000 timber samples at the Institute de Pesquisas Technologies. I narrowed the possibilities for my work down to nine, They were as follows:

Casalpinia ferraea, Swartzia fasciata, Astronium fraxinifolium, Coniorrhachis marginata, Diptadenie macrocarpa, Machaeriam villosar, Astronium macrocalyz, Dalbergia frutescens, and Ferreira spectabilis. Although most of the specimens selected may prove suitable for making guitars, some are, or will be shortly, as difficult as rosewood to obtain. Because of their close resemblance to rosewood, they have been sought as substitutes and used to make veneers and furniture.

As relief from the intense study in Bahia and l.P.T in São Paulo, I paid a visit to the guitar factory of Tranquillo Giannini, escorted by my friend Sergio Abreu. He is Brazil’s leading concert guitarist, and is called in by the company as a consultant to improve their instruments. They are very anxious to fill the needs of the professional guitarist, and could have chosen no better representative. My visit to the research and development department stimulated a lot of discussion, particularly on the use of new woods. The company had experimented with one or two new species with some success, but cracking had created some delays. Humidity in Brazil is extremely high, particularly in the South, and I was able to contribute from my own experience in workshop humidity control.

With the knowledge gained in Bahia and later at I.P.T., I felt confident in selecting a final seven woods to make up into guitars on my return. Although not all have the rich colour and beautiful grain pattern of the true Brazilian rosewood, the weight, density, flexibility and tone match sufficiently to give me the greatest chance of success.

Paul Fischer is a classical guitar maker of international repute, who produces about 40 instruments a year from his Chipping Norton workshop for top artistes such as Jason Vieaux and Xuefei Yang.

Collenette writes: A public ‘playoff’ of Paul Fischer’s seven guitars was held in London in October. John Mills performed — on the other side of an open doorway, so that his audience would not be influenced by the colours of the unfamiliar woods. The judges, seated among the throng, looked for projection, clarity, balance, sustain, response and tonal character. Each guitar had the traditional spruce soundboard and the same bracing pattern, but Fischer had used his professional skill to adjust thicknesses and other variables to produce a similar sound from all the instruments. In his estimation, the back and sides — that is, the parts fashioned here from new species — account for 20-25% of the tone colour.

The clear winner was Aruda De’Bolo (Swartzia Fasciata), which looks a lot like Brazilian mahogany. Joint second were kingwood (Dalbergia Cearensis) and brownheart (Ferreira Spectabilis), and princewood (Cordia Trichotoma) came in third. The question now must be whether the timber men will take the hint.

-

In 1992 Brazilian Rosewood was listed on CITES appendix 1.

-

CITES (the Convention of International Trade in Endangered Species)

Dr Bernard Richardson

Paul Fischer first met Dr Bernard Richardson in the late 1970’s and his work and study of musical instruments encouraged him to take a fresh look at the guitars construction. This lead on to the development of the TAUT system in the 1980’s. See Classical Guitar Magazine, January 1985

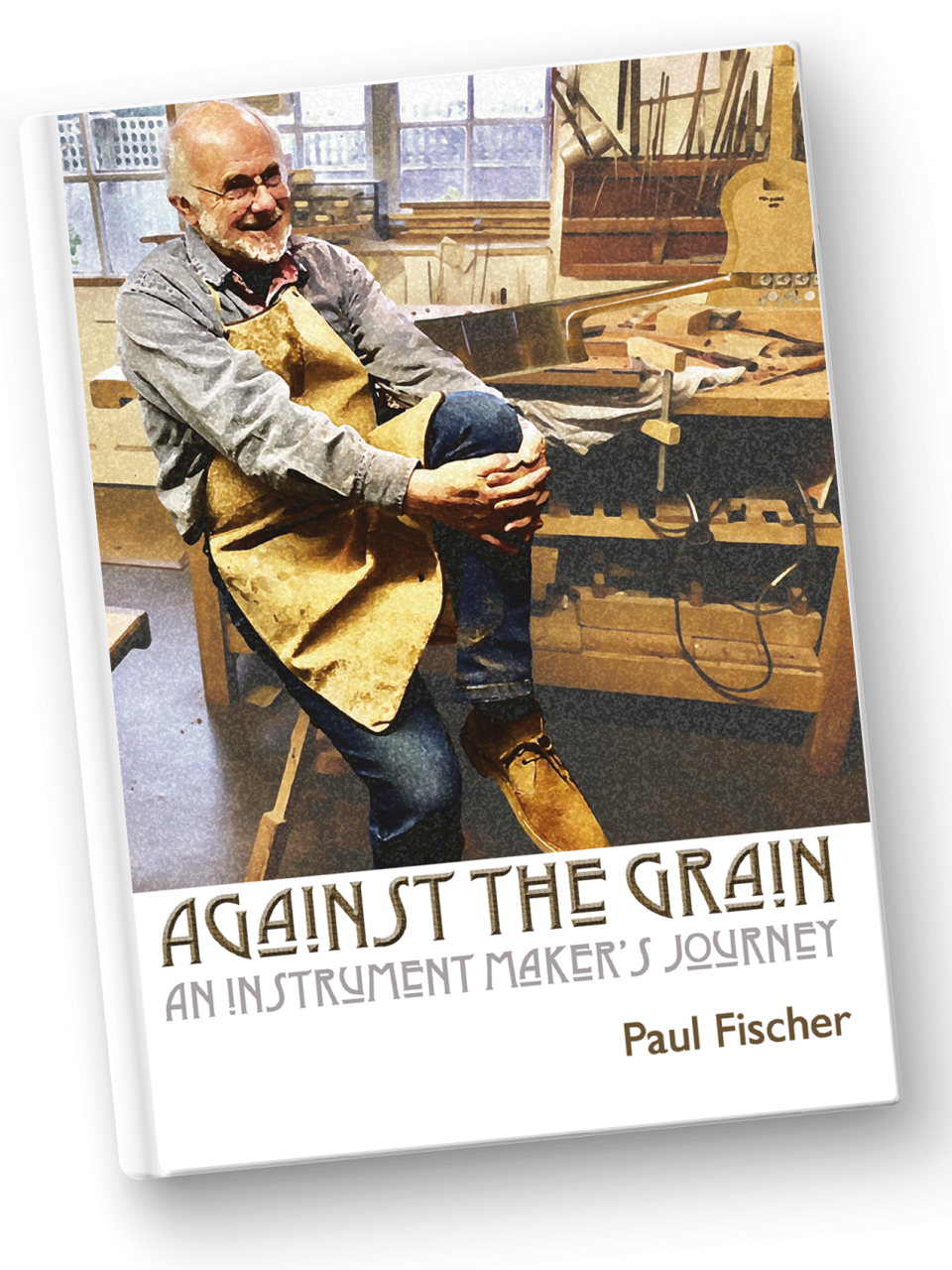

Against The Grain

The immense success Paul Fischer has achieved in a remarkable career is, of course, not only due to his amazing gifts but also sheer hard work, his energy, combined with a passionate belief in what he wanted to create. Therefore, with this fascinating publication, we celebrate his artistic contribution and his supreme talent.

John Mills

Available from:

Presto Music. Books.

23-25 Regent Grove. Leamington Spa. Warwickshire.CV324NN. U.K

email: info@prestomusic.com

Buy from Amazon

Paul Fischer

Luthier & Author

List of Players -

Past & Present

-

Pepe Martínez

Assad Brothers

Marcelo Kayath

Ruben Riera

Jukka Savioki

Amsterdam Guitar Trio

Eduardo Fernández

Badi Assad

John Mills

-

Jason Vieaux

Abreu Brothers

Gerald Garcia

Hill Wiltschinsky Duo

Paulo Bellinati

John Taylor

Omega Guitar Quartet

Forbes Henderson

Jason Waldron

Pavel Steidl

Juan Martin

Xuefei Yang